Crusher bearings are specifically designed for use in crushing equipment. They support the crusher’s rotating components, reduce friction during movement, and ensure rotational accuracy. Compared to ordinary bearings, crusher bearings must withstand greater loads, shock, and vibration, placing higher demands on material selection, structural design, and manufacturing processes. They are typically manufactured from high-strength bearing steel, offering excellent wear resistance, impact resistance, and fatigue strength to withstand the harsh operating environment of the crusher.Bearings play a role in supporting, transferring loads, reducing friction losses and ensuring rotation accuracy during the operation of crusher equipment.

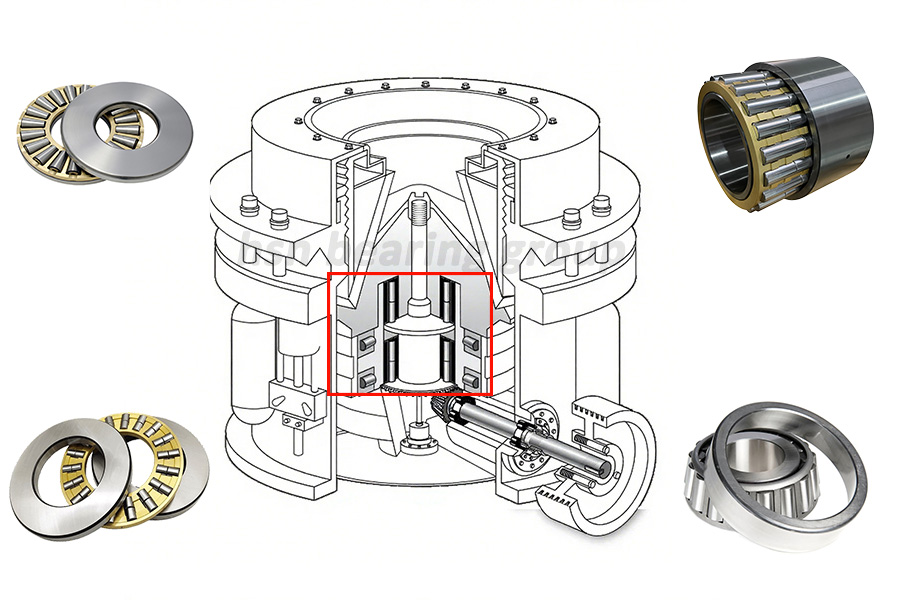

Cone crushers are primarily used for secondary and fine crushing. They consist of a frame, crushing cone, eccentric sleeve, and drive shaft. Their operating principle is that the crushing cone, driven by the eccentric sleeve, undergoes a swiveling motion, squeezing, impacting, and grinding the material. Tapered roller bearings are typically used between the crushing cone main shaft and the eccentric sleeve. These bearings can withstand both large radial and axial loads, offer high rigidity, and ensure stable operation of the crushing cone under high-speed oscillation and heavy loads. They are also easy to install and adjust.

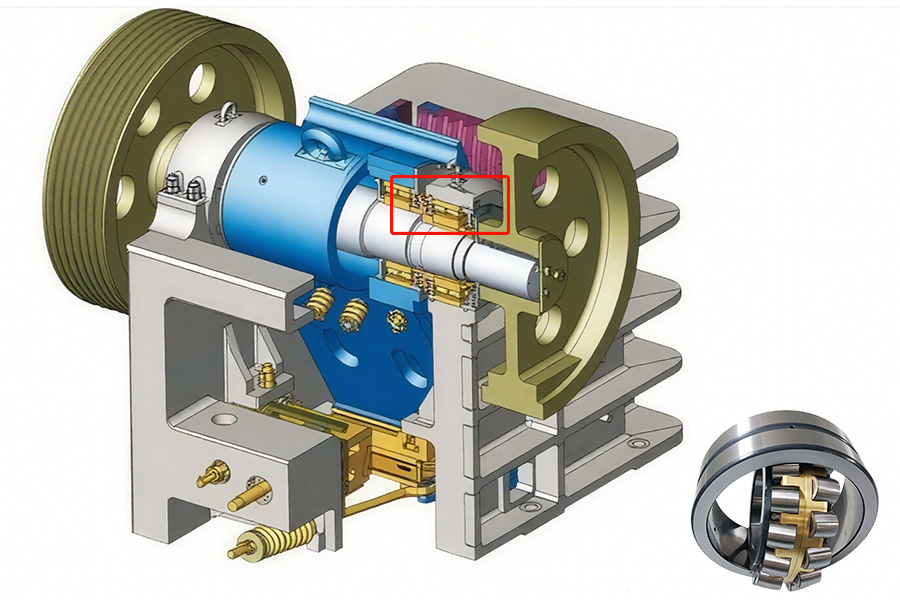

The jaw crusher is the primary crushing machine, consisting primarily of a frame, movable jaw, stationary jaw, and eccentric shaft. The periodic reciprocating motion of the movable jaw crushes materials, squeezing, splitting, and bending them. The eccentric shaft is the core rotating component in a jaw crusher, typically equipped with spherical roller bearings at both ends. These bearings offer excellent self-aligning properties, compensating for shaft installation errors and deflection during operation. They can also withstand large radial loads and moderate axial loads, making them ideally suited to the shock and vibration conditions generated by jaw crusher operation.

An impact crusher primarily consists of a frame, rotor, blow bars, and impact plates. The blow bars on the high-speed rotating rotor violently impact the material, causing it to repeatedly collide and break between the blow bars and impact plates. The rotor is the key rotating component of the impact crusher, and cylindrical roller bearings are typically used on its shaft. Cylindrical roller bearings offer a high radial load capacity, low friction coefficient, and high maximum speed, meeting the requirements of high-speed rotor operation. Furthermore, their separable inner and outer rings facilitate disassembly and replacement.

Impact crushers are suitable for crushing building materials and ore. A high-speed rotating impeller accelerates and throws materials, which then collide with the liner or material on the frame to crush them. The impeller shaft typically uses a combination of deep groove ball bearings and cylindrical roller bearings. The deep groove ball bearings primarily support axial loads, while the cylindrical roller bearings handle radial loads. This combination meets the force requirements of the high-speed impeller rotation and ensures stable operation.

| 10J15 | E-1307-B | 22332 MA | E-2259-A | 22344 CCJA |

| 10S47 | E-2267-A | 22338 MA | E-2311-A | 22319 CCJA |

| 11D63 | 22328 MA | 22348 MA | 22324 CCJA | 22324 CCJA |

| 13S84 | 22334 MA | 22319 MA | 22330 CCJA | 22330 CCJA |

| 13Y77 | 22319 MA | 22324 MA | 22336 CCJA | 22336 CCJA |

| 13Y82 | 22324 MA | 22330 MA | 22344 CCJA | 22344 CCJA |

| 13Y88 | E-2408-A | 22336 MA | 22319 CCJA | 22319 CCJA |

| 14S95 | 22330 MA | 22320 MA | 22328 CCJA | 22324 CCJA |

| 16T81 | 22326 MA | 22326 MA | 22338 CCJA | 22330 CCJA |

| J-900-A | 22336 MA | 22332 MA | 22326 CCJA | 22344 CCJA |

| P-1761-C | S-3181-C | S-4789-A | 22334 MA | 22340 CCJA |

| Z-525487.AR | Z-545106.AR | 22324 MA | Z-562614.AR | 22328 CCJA |