Dump trucks must withstand havey contaminant and extreme loads. That requests the durability and reliability of the bearings.

Bearings in jaw crushers support the movable jaw and provide smooth operation by transferring the load of the movable jaw to the frame and ensuring that it rotates smoothly against the fixed jaw. It can also help reduce friction between the surfaces in contact, thereby minimizing wear and tear and preventing overheating of the components, which could otherwise lead to premature failure.

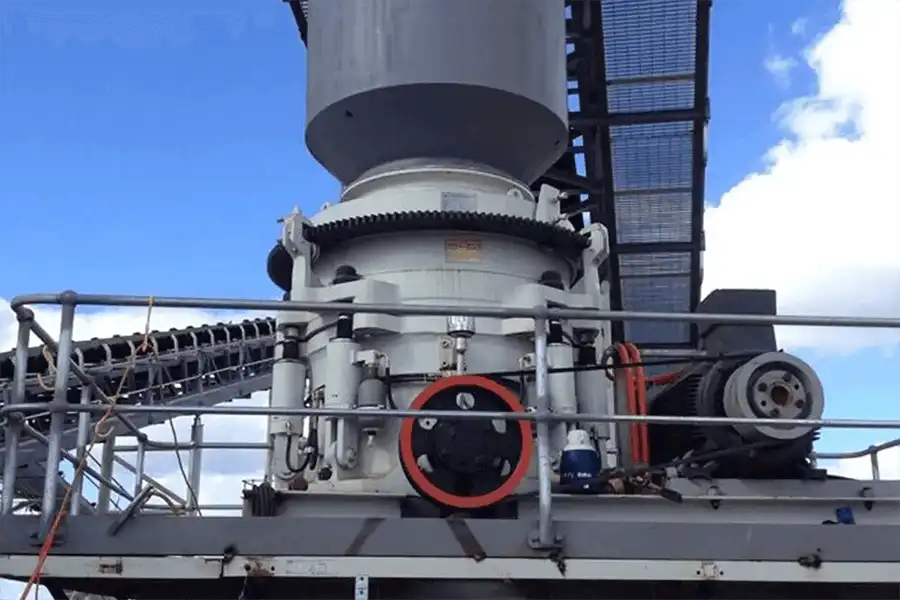

Bearings are essential in cone crushers to support heavy loads, facilitate smooth operation, manage heat and friction, and maintain the crusher’s structural integrity over its operational life.

Bearings are integral to vibrating screens as they support rotating shafts, handle vibrational forces, reduce friction and wear, ensure smooth operation, and support heavy loads. They contribute significantly to the efficiency, reliability, and longevity of vibrating screen equipment.

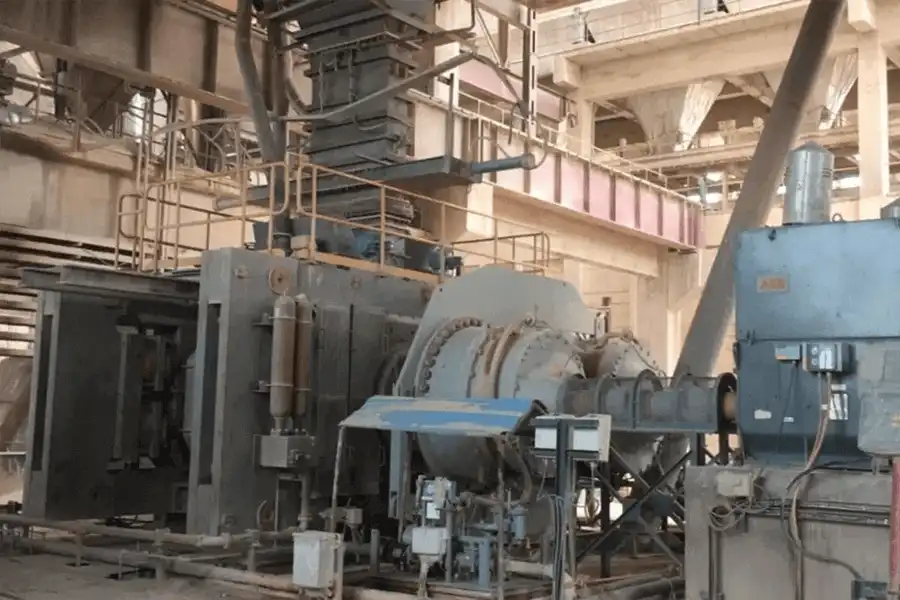

Rotary kiln means ultra high investment for cement industry. At full capacity, rotary kilns are in operation 24h x 7. The unexpected downtime will result in extremely high costs and damage.

In vertical roller mill, the heavy dynamic loads impacting the bearings, therefore, the bearings must have radial and axial load carrying capacity in a limited mounting space.

Spherical roller bearings are predominantly used in roller presses because of high load carrying capacity and ability to compensate misalignment.

Ball mills are subjected to extreme fluctuations in temperature. That requests reliability and high performance of the bearings.

Conveyor systems move countless amounts of material across long distances every day. Various types of rolling bearings are found in gearboxes, pulleys and idlers.