The steel mill industry represents one of the most demanding environments for bearing performance—extreme temperatures, heavy impact loads, dust contamination, and round-the-clock operation. A bearing failure at any stage can halt the entire production line, resulting in millions of dollars in losses. Therefore, selecting high-quality bearings is not just a “cost upgrade,” but a strategic necessity for steel mills to ensure stable production, control overall operational costs, and strengthen core competitiveness.With “exceptional tolerance to extreme conditions and long-term operational stability” at its core, HSN Bearings offers cost-effective bearing solutions across the entire steelmaking process, helping steel mills reduce costs, improve efficiency, and ensure safe production.

With 30 years of professional manufacturing experience, HSN bearings are widely applied in harsh working conditions involving high temperatures, heavy loads, dust, and impact forces. Below is an overview of the main equipment compatible with HSN bearings:

Roll neck bearings are core components of rolling mill equipment, bearing the high loads, high speeds, and impact forces generated during the rolling process, ensuring smooth operation and precise alignment of the rolls. High-performance bearings not only maintain rolling accuracy but also reduce vibration and wear, improving production efficiency. HSN roll neck bearings are heat-resistant, shock-proof, and long-lasting, providing reliable support for rolling mills and ensuring continuous, stable production of high-quality steel.

Converter bearings are key components in steelmaking equipment, enduring high temperatures, heavy loads, and impact forces during the steelmaking process to ensure smooth rotation and precise positioning of the converter. High-performance bearings effectively reduce friction and wear, enhancing equipment reliability and production efficiency. HSN converter bearings are heat-resistant, shock-proof, and long-lasting, providing stable support for steelmaking equipment, ensuring continuous and efficient steel refining, and contributing to the production of high-quality steel.

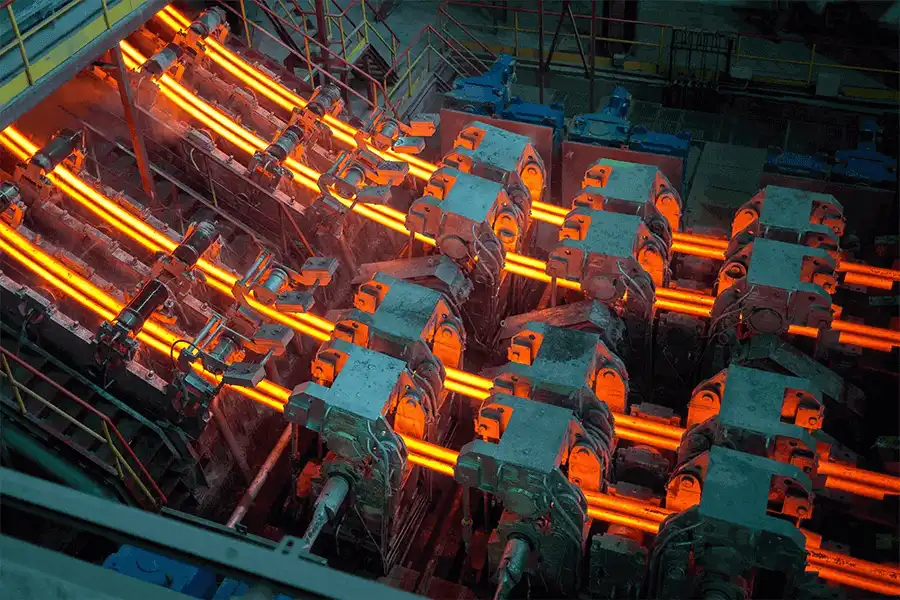

Continuous caster bearings are core components of continuous casting equipment, enduring the high loads, impact forces, and tilting moments generated by the ladle turret and casting segments during steelmaking. They ensure smooth rotation and precise alignment of the turret and rollers. High-performance bearings reduce friction and wear, enhancing equipment stability and production efficiency. HSN continuous caster bearings are heat-resistant, shock-proof, and long-lasting, providing reliable support for continuous casting equipment, ensuring uninterrupted, efficient solidification of molten steel, and contributing to the production of high-quality steel.

Four-row Cylindrical Roller Bearings: 316967, BC4-8002/HA6, BC4B320525, NNUD60/750M, BC4B420625

Four-row Tapered Roller Bearings: BT4B334016G-HA1VA901, 353132, 353130

Spherical Roller Bearings: 22224CA/W33, 24038CC/W33, 23236CC/W33, 23964CC/W33, 24048CC/W33

Double-row Tapered Roller Bearings: 32218/DF, NA46790SW/46720, 30220/DB

Angular Contact Ball Bearings: 305608, 234420, 506871

As a key sector of heavy industry, steel mills operate equipment under prolonged exposure to extreme temperatures, heavy loads, dust, and impact, placing rigorous demands on bearing heat resistance, wear resistance, and impact durability.

Drawing on extensive industry experience, HSN Bearings provides specialized bearing solutions tailored to core steel plant equipment such as rolling mills, continuous casting machines, and blast furnace blowers. These products can serve as direct replacements for leading global brands like SKF and FAG, combining stable quality with significant cost advantages—resulting in broad market potential within the steel industry.

To further expand market reach and better serve end users, we are now officially launching a distributor recruitment program for the steel sector. By leveraging the regional resources and industry networks of our distribution partners, we aim to jointly explore market opportunities and achieve sustainable, collaborative growth.