Wind turbines operate in environments characterized by openness, complexity, and extreme conditions. This places stringent requirements on the weather resistance, corrosion resistance, and load-bearing capacity of core components such as bearings, gearboxes, and blades. Precise manufacturing processes and rigorous quality control are crucial to ensuring that these bearings meet the demands of the wind energy industry.

HSN Bearings focuses on providing high-reliability solutions throughout the entire lifecycle of wind turbines. We collaborate closely with leading Chinese manufacturers to offer cost-effective products and services. In response to the wind power industry’s challenges of high loads, extreme temperatures, complex alternating stresses, and high maintenance difficulty, our products fully satisfy the stringent requirements of both onshore and offshore wind power equipment. They are backed by the R&D capabilities, technical expertise, and service strengths of top-tier manufacturers.

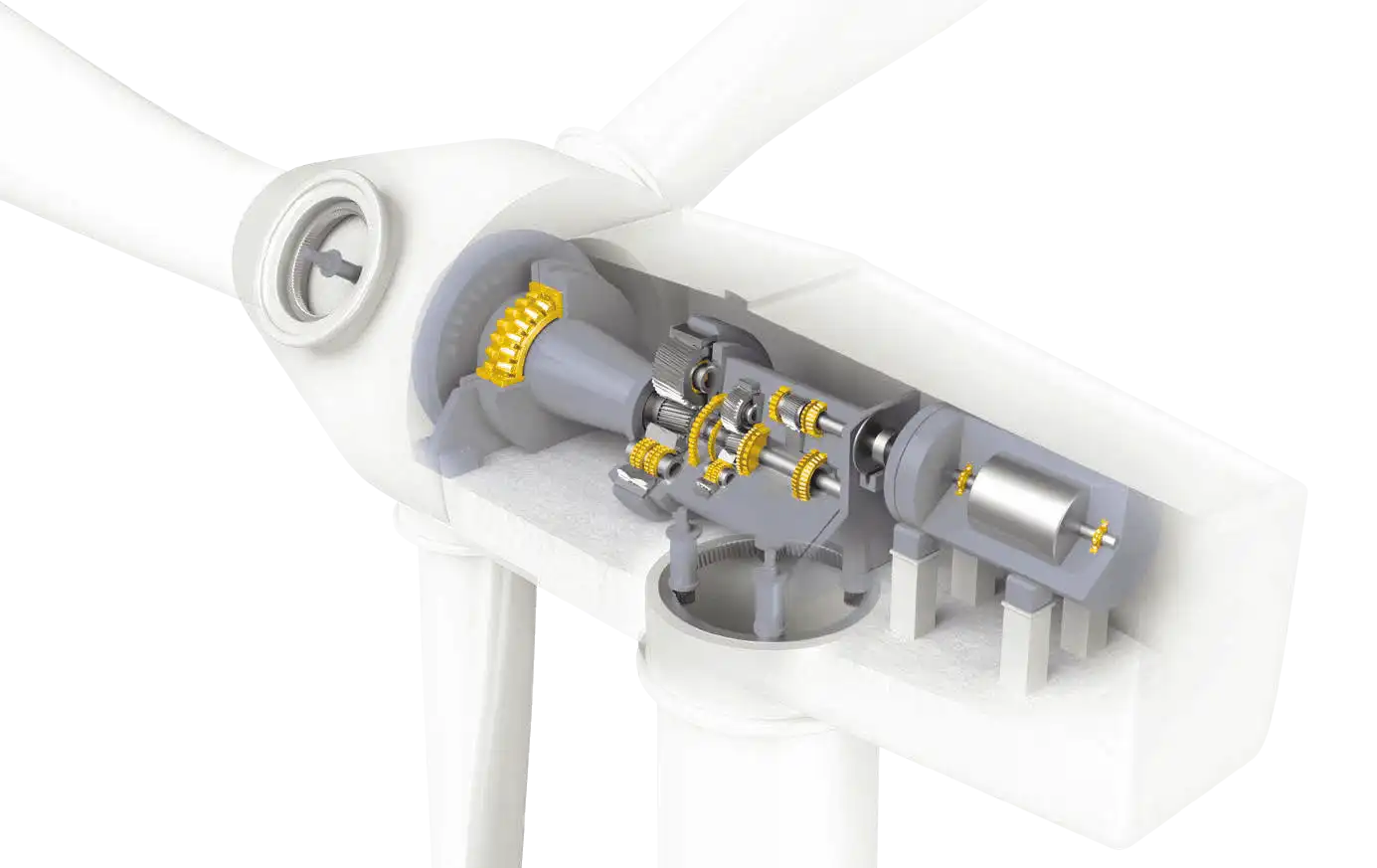

We specialize in the R&D and manufacturing of wind turbine bearings, working in close collaboration with leading domestic manufacturers. Our products are compatible with globally renowned brands such as Vestas, Siemens Gamesa, and GE Renewable Energy. Covering main shaft bearings, yaw bearings, gearbox bearings, and generator bearings, our products feature high load capacity, impact resistance, and long service life, effectively ensuring the continuous and efficient operation of wind turbines under complex wind conditions and high loads.

The main shaft bearing is one of the core components of a wind turbine, directly supporting the full load transmitted from the blades and driving the generator. The bearing must accommodate both axial and radial loads while operating stably under harsh conditions. Its key features include:

The yaw bearing enables the nacelle to “face the wind,” while the pitch bearing controls the blade “angle adjustment.” Both must withstand complex loads in extreme environments. Their characteristics include:

The gearbox bearing handles composite loads from wind forces, gear meshing stresses, and speed variations. It also plays a key role in increasing turbine speed and converting wind energy into electricity. Its features include:

Generator bearings support the wind turbine generator rotor, enabling smooth, efficient, and low-noise energy conversion. These bearings must remain stable under high-speed, low-friction conditions. Their features include:

| Spherical Roller Bearings | 240/950EW33MH-WFHD | 230/670CA/W33 | 231/750 CAK/W33 | 24068CCK30/W33 | 230/670CA/W33 | BS2-2218-2RS/VT143 |

| Cylindrical Roller Bearings | NU29/670 | NU3096 | NU18/850 | NU2326ECML | NJ1030ECML | NU3184M |

| Tapered Roller Bearings | PSL612-395 | Z-531295.01.TR2 | Z-578815.TR2 | Z-534867.TR2 | T7FC 070 | HM218248/10 |

| Electrically Insulated Bearings | 6236-J20AA-C3 | 6226M/C3VL0241 | 6228M/C3J20AA | NU320EM/C3V3031A | NJ2314EM/C3VL2071 | NU315ECM/C3VA3091 |

| Slewing Bearings | PSL912-305A | RKS.230741 | XSA 140414 N | RKS.160.16.1644 | XSU 140824 | QAD 2400.600/600 |

With the wind power industry booming under the dual-carbon targets, equipment often operates under extreme conditions. Wind turbine bearings must therefore exhibit characteristics such as low speed, high load capacity, resistance to salt spray and sandstorms, and long service life. Their reliability is of paramount importance. HSN has established long-term strategic partnerships with leading Chinese manufacturers. Leveraging strong R&D and production capabilities, we ensure that every batch of bearings meets the stringent standards of the global wind energy industry, providing end-to-end support for new wind farm projects as well as operation and maintenance services. We are committed to delivering high-quality products that help extend the lifespan of wind turbines and enhance their operational efficiency.