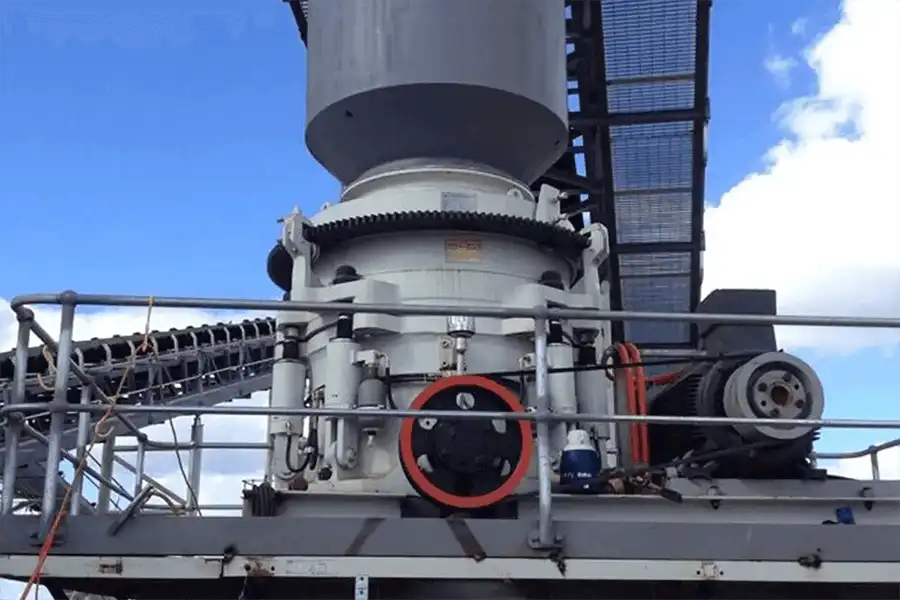

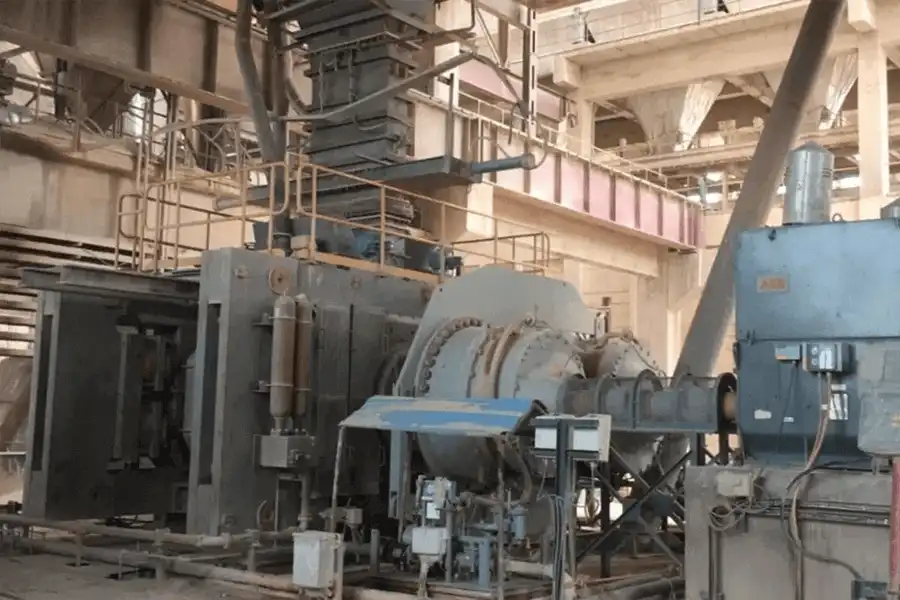

In the mining and cement industries, equipment operates under heavy loads, high temperatures, dust, and impacts year-round, with 24/7 continuous operation. Bearings are therefore a core factor determining capacity, cost, and safety. While ordinary bearings may seem to have a lower initial investment cost, frequent failures often lead to cascading losses. Choosing high-quality bearings, on the other hand, is a long-term investment in production stability, overall efficiency, and compliance.

Whether you face high temperatures in steel mill rolling mills, heavy-load impacts in mining machinery, or dust erosion in cement equipment, HSN provides precisely tailored bearing solutions to ensure equipment operational stability and lifespan.

As a heavy industry sector, the mining and cement industries have complex production processes and rely heavily on large-scale complete sets of equipment. Core equipment spans the entire chain of “raw material extraction – processing – conveying – finished product output,” and all critical operating parts require high-quality bearings for support. The following are classifications of core mechanical equipment in these two industries: