Creation on:2025/12/19

There are many types of mud pumps, but this section focuses on those used in the oil and gas drilling industry. Global oilfield production areas include the Middle East, Russia, the United States, the Caribbean, and North Africa.Mud pump equipment manufacturers mainly used in the oil and gas drilling and production industry: Flowserve, Weir Group, Sulzer, KSB, Grundfos, National Oilwell Varco(NOV), Schlumberger, Gardner Denver, Weatherford, etc.

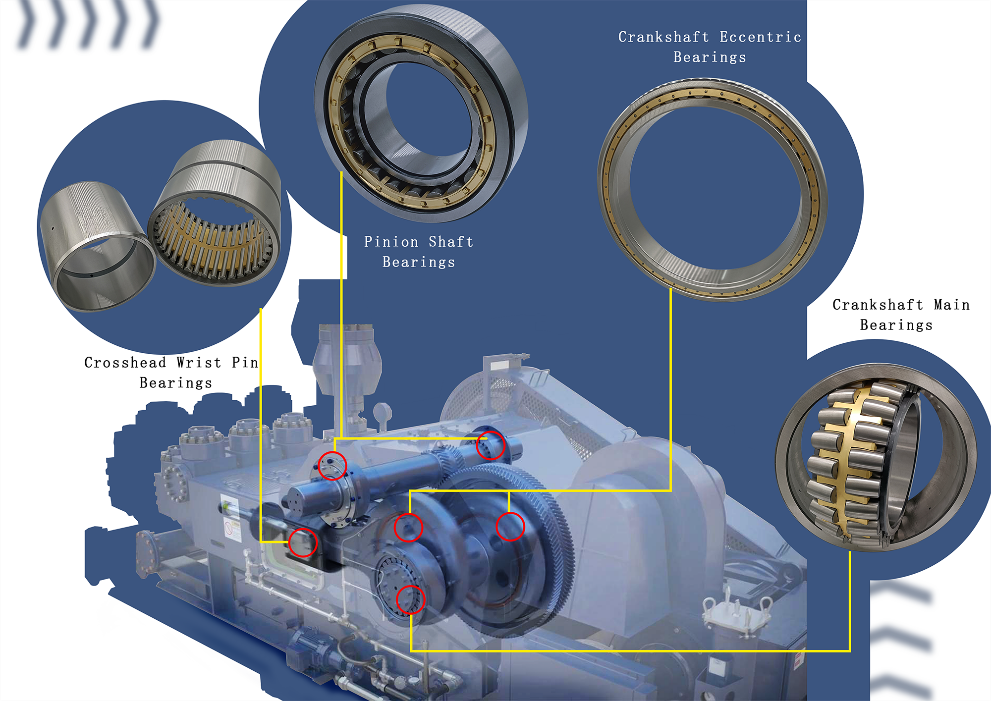

Since each mud pump manufacturer has its own design, different brands of mud pumps use different types of bearings. Next, I’ll introduce the main types of bearings used in mud pumps.

In mud pump equipment, spherical roller bearings, cylindrical roller bearings, and tapered roller bearings are the absolute mainstream and preferred types.

1.Spherical roller bearings:

These bearings are commonly used in both the non-drive end (NDE) and drive end (DE) of slurry pumps, where they serve as the core component supporting the pump rotor.

Their outer ring raceway is spherical, allowing the inner ring, rollers, and cage to self-align within a certain range. This feature is especially crucial for slurry pumps due to the following reasons:

Another key advantage is their high load-carrying capacity: equipped with two rows of rollers, these bearings are designed to withstand both very high radial and axial loads. In slurry pumps, the weight of the impeller and hydraulic radial forces—generated by pumping pressure—primarily produce radial loads. Meanwhile, axial forces, which depend on the impeller design, also need to be reliably supported by the bearings.

2.Cylindrical Roller Bearings:

Extremely High Radial Load Capacity.

Due to the fact that their rollers and raceways are in line contact and they typically incorporate a large number of rollers, the effective contact area is very large. As a result, cylindrical roller bearings offer the highest radial load capacity per unit size among all types of rolling bearings.

Compact Design, Space Savings

For the same radial load, cylindrical roller bearings generally require less radial installation space—being thinner compared to spherical roller bearings. This makes them particularly advantageous in the design of compact slurry pumps.

3.Tapered roller bearings:

These are commonly used in medium-sized pumps or in applications that require precisely controlled axial clearance. In certain slurry pump designs, they are installed at the drive end to carry the primary axial thrust. Tapered roller bearings can withstand both significant radial and unidirectional axial loads. They are typically installed in pairs—either back-to-back or face-to-face—in order to support bidirectional axial thrust.

For mud pump maintenance in the oil and gas extraction industry, HSN offers a wide range of mud pump bearings in stock. The main mud pump brands and their model numbers are included:

Pump Manufacturer | Pump No. | ||||

NOV® | 9P-100 | 10P-130 | 12P-160 | 14P-220 | F-500 |

Emsco®(NOV®) | F800 | F1000 | F1300 | F1600 | F1700 |

Gardner Denver® | PZ7 | PZ8 | PZ9 | PZ10 | PZ11 |

Among them, the most popular series is the F series, with the F1600 model being the most widely used mud pump worldwide. At present, the F series mud pumps are mainly produced in China. Well-known Chinese manufacturers include Dahongli, LS Group, and Baoji Oilfield Machinery (BOMCO).

HSN Company has rich experience in mud pump bearings, understanding the corresponding bearing model for each mud pump and the different bearing quality manufacturing processes.

We aim to provide you with the most suitable mud pump bearings — please feel free to contact our sales department for more information.

Tel: 86.156.6578.7336 Email: service@hsnindustrial.com Website: www.rollingparts.com www.hsnbearing.com

Compact Needle Roller Bearings

engineered to withstand high radial loads with minimum cross-section, ideal for space-constrained assemblies. Available in open or sealed designs.