Creation On:2025/12/09

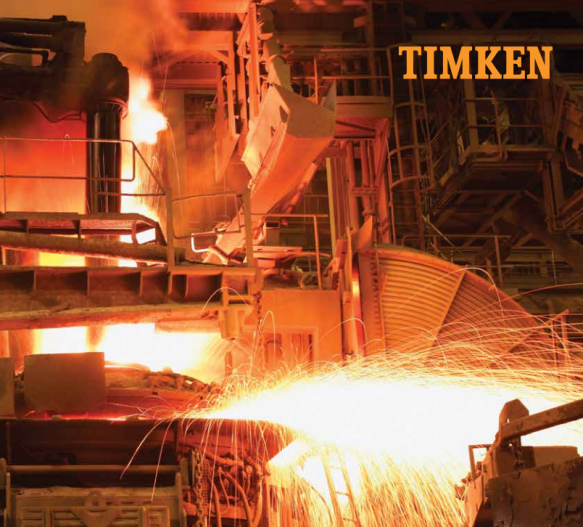

Modern metallurgical equipment demands significantly increased load capacity, speed, and precision. Continuous operation and stability have become key to production. In the metallurgical field, TIMKEN provides tailored bearing systems for different process conditions and operational scenarios.

Continuous casting represents an extreme operating condition for bearing applications. Roller system support bearings must withstand high temperatures, heavy loads, and low-speed wear. Adapted solutions include:

Roll necks in rolling mills must withstand extremely high radial loads and dynamic axial loads, placing stringent demands on bearing strength and suitability. Bearings feature high-precision contact surfaces, high-strength base materials, and other characteristics. Core products include:

Auxiliary equipment such as gearboxes and coilers operate under diverse conditions, requiring combined load-bearing capabilities. Among them, double-row tapered roller bearings can withstand combined radial and axial loads. Paired with robust sealing designs, they are suited for high-frequency operation, reducing downtime for maintenance.

Mill stands equipped with cylindrical roller bearings or oil film bearings, or rolling mills employing processes like roll shifting,require thrust bearings to counteract axial forces. Core solutions include:

In summary, bearing solutions are customized for various metallurgical process conditions, providing comprehensive support from core processes to auxiliary systems. This ensures efficient and stable equipment operation while enhancing finished product quality.

1. Regarding detailed TIMKEN bearing models except above-listed, please contact HSN.

2. For other types of bearings, please contact HSN.

3. This article is based on independent analysis of publicly available technical information and industry understanding, and aims to provide knowledge sharing. All brand names and trademarks mentioned in this article belong to their respective owners. HSN Bearing Group is an independent bearing supplier and technical service provider.

Tel: 86.156.6578.7336 Email: service@hsnindustrial.com Website: www.rollingparts.com www.hsnbearing.com