Creation on:2025/10/11

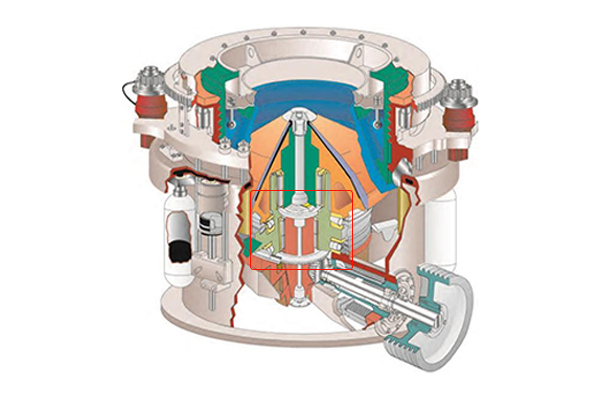

Globally renowned crusher manufacturers include Metso, Sandvik, Terex, Svedala, Eagle Crusher, Kleemann, Astec Industries, Thyssenkrupp, SANME, CITIC HIC, and Liming Heavy Industry. As core equipment in industries such as mining, building, metallurgy, chemicals, and power plants, crushers can be primarily categorized by their structure and operating principle: jaw crushers, gyratory crushers, cone crushers, impact crushers, hammer crushers, roll crushers.

(1) Material Hardness:

(2) Feed Size:

(3) Product Requirements:

(4) Production Scale:

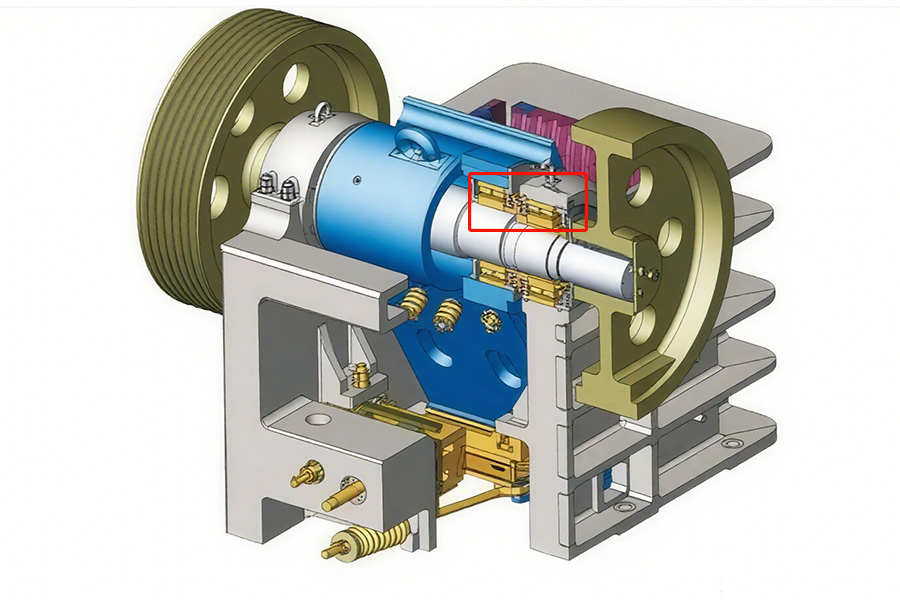

Crushers are constantly exposed to high loads, strong impacts, high dust levels and poor lubrication conditions, bearings as it’s core transmission components, have a significant impact on the equipment’s service life and operational stability. Due to differences in structure and load characteristics, each parts commonly use different bearings. Below are our introduce of the main rolling bearing types used in crushers:

(1) Spherical roller bearings(223/231/232/240 series)

Spherical roller bearings can withstand strong impact and eccentric loads, commonly used in the core and eccentric shafts of jaw crushers, cone crushers, gyratory crushers, impact crushers, hammer crushers and roller crushers.

(2) Thrust roller bearings

Thrust roller bearings are mainly used at the lower end of the main shaft/the bottom of the moving cone to support and share the axial load.

(3) Cylindrical roller bearings

Cylindrical roller bearings are resistant to high temperatures and shocks, can withstand combined radial and axial loads. They are primarily used in key support positions in cone crushers, roller crushers, and impact crushers.

Different brands and models of crushers use different types of bearings, and the quality requirements also vary depending on the installation position. Cone crushers mainly adopt a combination of Thrust roller bearings and Cylindrical roller bearings, while some Chinese-made cone crushers use Single-row Tapered roller bearings. Other types of crushers primarily mainly use small and medium-sized Spherical roller bearings and Single-row Cylindrical roller bearings.

Because crusher bearings operate under extreme conditions—such as high impact, heavy loads, severe contamination, and wide temperature fluctuations—HSN’s engineers have leveraged their extensive expertise in bearing manufacturing to enhance production processes in multiple aspects, including raw material selection, inner and outer ring wall thickness optimization, roller design, cage structure, and surface strengthening treatments. These improvements ensure a service life of over one year and allow HSN bearings to fully replace SKF and FAG equivalents. In addition, HSN maintains a comprehensive inventory of various types of crusher bearings, meeting procurement needs for bearings of different quality levels.

If you have any purchase needs for Crusher bearings, please feel free to contact us.

To learn more about bearings, please follow our social media accounts.

Tel: 86.156.6578.7336 Email: service@hsnindustrial.com Website: www.rollingparts.com www.hsnbearing.com

11