Creation on:2025/09/12

Related keywords:Vertical Mill Bearing , Bearings for Cement Plants , Pulverizer Bearings , Bearings for Vertical Rolling Mills , Bearings for Vertical Roller Mills , Bearings for Vertical Grinding Mills , Grinding Roller Bearings and Gearbox Bearings.

World-renowned cement equipment manufacturers include: FLSmidth, LOESCHE, Gebr. Pfeiffer SE, Polysius, UBE Machinery. Each company occupies a distinct market share, leveraging the technological advantages of its equipment.

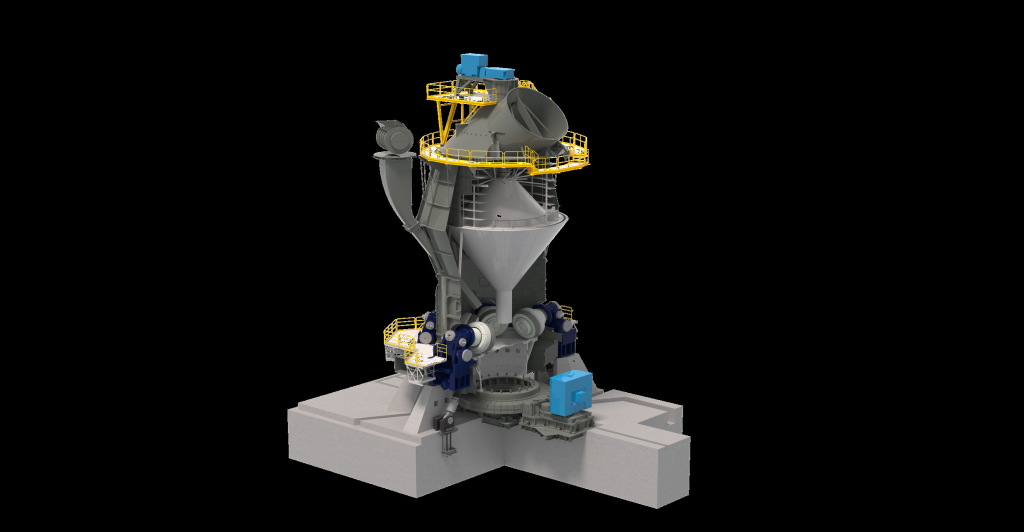

There are many types of equipment used in cement plants, among which the equipment that uses bearings more frequently include: Kilns, Clinker coolers, Roller presses, Vertical grinding mills, Bucket elevators, Cement mills, etc. Among them, Vertical grinding mills use bearings most frequently.

VRMs use large, high-capacity bearings in two main locations: the grinding roller assemblies and the mill gearbox.

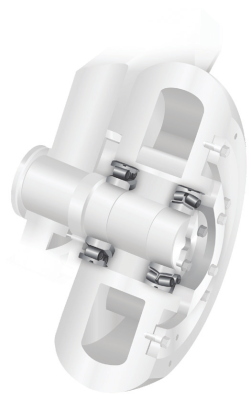

1.Grinding roller bearings

The roller assembly experiences extremely high radial loads (from the grinding pressure) and axial (thrust) loads. The following bearings are commonly used for this purpose:

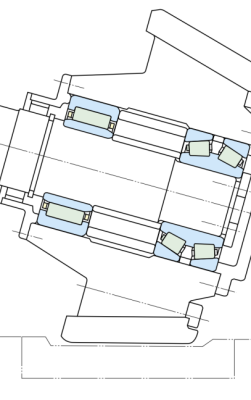

2.Gearbox bearings

The gearbox, which drives the rotation of the grinding table, also utilizes heavy-duty bearings to transmit power efficiently:

Different companies have different design philosophies, so the bearing structures used in the same equipment components can vary. For example, in Grinding rollers, some designs use a combination of spherical roller bearings and single-row cylindrical roller bearings, while others use a combination of double-row tapered roller bearings and single-row cylindrical roller bearings. As shown below:

Since each cement plant may purchase different cement equipment, HSN has various types of bearings in stock to meet the bearing procurement needs of different cement plants.

If you have any purchase needs for vertical roller mill bearings, please feel free to contact us.

To learn more about bearings, please follow our social media accounts.

Tel: 86.156.6578.7336 Email: service@hsnindustrial.com Website: www.rollingparts.com www.hsnbearing.com

11